Drilling Buckets

Built for efficiency and strength—optimized for fast and precise soil and rock excavation in foundation drilling.

Drilling Buckets

For bored pile foundation construction, rotary drilling buckets come in different types to suit various ground conditions. Below are the two most commonly used types:

Rock Drilling Bucket – Equipped with bullet teeth, this bucket is ideal for drilling through challenging formations such as sand and gravel layers, pebble beds, flagstone, high-strength frozen soil, weathered rock, and other complex hard strata.

Soil Drilling Bucket – Designed with flat teeth (e.g., 18T, 25T), this bucket is best suited for water-bearing cohesive and non-cohesive soils, clay, silt, and loose to medium-dense sand and gravel, including coarse gravel.

Selecting the right drilling bucket is essential for maximizing efficiency and achieving precise excavation results. Siderwin provides expert recommendations to help you choose the optimal bucket for your project.

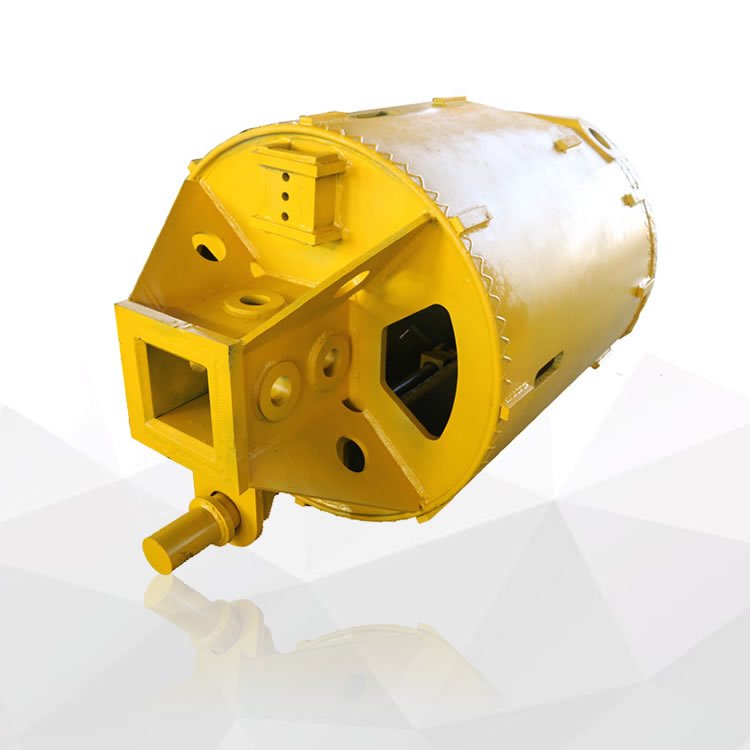

Drilling Bucket with Rock Drilling Teeth

Feature:

Option half-automatic or manul mechanic bottom open system. Built-in ventilation pipe;

Cast pilot with rock drilling bits , arc guide plate teeth arrangement, double unlocking system;

Staggered arrangement of rock drilling bits;

Applicable layers: gravel , pebble , highly or medium weathered rock;

Model List

Cutting Dia | Shell HIT | Shell OD | Shell THK | Fixed Bottom THK | Rotate Bottom THK | Teeth No | Weight |

φ600 | 1200 | 500 | 16 | 40 | 40 | 6 | 650 |

φ800 | 1200 | 700 | 16 | 40 | 50 | 9 | 950 |

φ900 | 1200 | 800 | 16 | 40 | 50 | 10 | 1100 |

φ1000 | 1200 | 900 | 16 | 40 | 50 | 11 | 1230 |

φ1200 | 1200 | 1100 | 16 | 40 | 50 | 13 | 1580 |

φ1500 | 1200 | 1400 | 16 | 40 | 50 | 16 | 2060 |

φ1600 | 1200 | 1500 | 16 | 40 | 50 | 17 | 2430 |

φ1800 | 1000 | 1700 | 20 | 50 | 50 | 21 | 3400 |

φ2000 | 800 | 1900 | 20 | 50 | 50 | 22 | 3900 |

φ2200 | 800 | 2100 | 20 | 50 | 50 | 23 | 4400 |

φ2500 | 800 | 2400 | 25 | 50 | 50 | 27 | 5800 |

φ2800 | 800 | 2700 | 25 | 50 | 50 | 33 | 6800 |

φ3000 | 800 | 2900 | 25 | 50 | 50 | 35 | 7700 |

Remark : The length is in milimeters, weight in kilograms.

Customizable Items:

Cutting DIA. Custom : design various cutting diameter based on demand, like φ950、φ1050 etc.

Shell HIT. Custom : design as demand, prolong or shortten, increase of efficiency by drilling more.

Key Component Reinforce Custom : strengthen the key component to extend life cycle;

Cutter Custom: single cutter and double cutter design as demand;

Bottom Custom : single bottom and double bottom design as demand;

Kelly Box Custom : custom kelly box size based on the kelly bar, like 130*130, 150*150,200*200 etc;

Bottom Open Mechanic : half-automatic or manul mechanic bottom open system.

Drilling Bucket with Soil Drilling Teeth

Feature:

Applicable scope: silt, gravel, clay and highly weathered rock;

Model List

Cutting Dia | Shell HIT | Shell OD | Shell THK | Fixed Bottom THK | Rotate Bottom THK | Teeth No | Weight |

φ600 | 1200 | 500 | 16 | 40 | 40 | 4 | 640 |

φ800 | 1200 | 700 | 16 | 40 | 50 | 4 | 900 |

φ900 | 1200 | 800 | 16 | 40 | 50 | 5 | 1050 |

φ1000 | 1200 | 900 | 16 | 40 | 50 | 5 | 1200 |

φ1200 | 1200 | 1100 | 16 | 40 | 50 | 7 | 1550 |

φ1500 | 1200 | 1400 | 16 | 40 | 50 | 9 | 2050 |

φ1600 | 1200 | 1500 | 16 | 40 | 50 | 9 | 2250 |

φ1800 | 1000 | 1700 | 20 | 50 | 50 | 12 | 2700 |

φ2000 | 800 | 1900 | 20 | 50 | 50 | 14 | 3260 |

φ2200 | 800 | 2100 | 20 | 50 | 50 | 16 | 4330 |

φ2500 | 800 | 2400 | 25 | 50 | 50 | 19 | 5400 |

φ2800 | 800 | 2700 | 25 | 50 | 50 | 22 | 6630 |

φ3000 | 800 | 2900 | 25 | 50 | 50 | 24 | 7400 |

Remark : The length is in milimeters, weight in kilograms.

Customizable Items:

Cutting DIA. Custom : design various cutting diameter based on demand, like φ950、φ1050 etc.

Shell HIT. Custom : design as demand, prolong or shortten, increase of efficiency by drilling more.

Key Component Reinforce Custom : strengthen the key component to extend life cycle;

Cutter Custom: single cutter and double cutter design as demand;

Bottom Custom : single bottom and double bottom design as demand;

Kelly Box Custom : custom kelly box size based on the kelly bar, like 130*130, 150*150,200*200 etc;

Bottom Open Mechanic : half-automatic or manul mechanic bottom open system.

Flat Teeth Custom : equip with V20, FZ80, FZ72, 22S, TL18,TL25, etc, as working condition demand .

Contact us to get a catalog

We’re happy to assist you in finding the best product for your application

+86-15388967455

+86-15388967455