At Siderwin, we engineer bucket teeth for performance, durability, and total cost efficiency

1. What Are Bucket Teeth?

At Siderwin, we define bucket teeth as critical ground-engaging tools installed on excavator, loader, and mining buckets. They are not simple consumables. Bucket teeth directly determine how efficiently a machine penetrates material, how much fuel it consumes, and how much stress is transferred to the bucket and undercarriage.

In our daily cooperation with contractors, quarry operators, and equipment distributors, we see that bucket teeth performance affects:

- Digging efficiency and cycle time

- Fuel consumption per cubic meter

- Bucket lip and adapter protection

- Machine stability under load

- Overall operating cost per hour

That is why at Siderwin, we design and manufacture bucket teeth with a system mindset, not just as individual parts.

2. Why Bucket Teeth Quality Matters

At Siderwin, we often hear customers say, “Bucket teeth all look similar.”

From our manufacturing and field experience, this is not true.

Low-quality bucket teeth usually result in:

- Rapid wear and frequent replacements

- Sudden tooth breakage under impact

- Adapter nose damage

- Increased downtime and labor cost

At Siderwin, we focus on long-term performance, not short-term price advantages. High-quality bucket teeth allow our customers to:

- Extend service life

- Maintain consistent digging performance

- Reduce unexpected failures

- Lower total cost per working hour

This philosophy guides every step of our production.

3. Main Types of Bucket Teeth at Siderwin

3.1 Standard / General Purpose Bucket Teeth

At Siderwin, our standard bucket teeth are designed for balanced performance.

Typical applications:

- Soft soil

- Sand

- Loam

- Light gravel

Key characteristics:

- Stable penetration

- Uniform wear pattern

- Cost-effective solution for general construction

These teeth are widely used in municipal projects, trenching, and foundation work.

3.2 Rock Bucket Teeth (Chisel Teeth)

Our rock bucket teeth are engineered for higher stress and abrasion.

Typical applications:

- Compact clay

- Hard soil

- Medium rock

Key characteristics:

- Reinforced tip design

- Improved wear resistance

- Strong impact tolerance

At Siderwin, rock teeth are frequently selected for infrastructure and quarry preparation work.

3.3 Tiger Bucket Teeth (Penetration Teeth)

At Siderwin, tiger teeth are designed to maximize penetration efficiency.

Typical applications:

- Hard rock

- Fractured stone

- Frozen ground

Key characteristics:

- Narrow, aggressive profile

- Reduced digging resistance

- Faster material breakage

Many of our customers combine tiger teeth in the center positions with standard or rock teeth on the sides for optimized performance.

3.4 Heavy-Duty Bucket Teeth

For extreme environments, at Siderwin we offer heavy-duty bucket teeth.

Typical applications:

- Mining

- Quarry

- Highly abrasive materials

Key characteristics:

- Extra-thick wear material

- Extended service life

- High impact resistance

These teeth are designed for long service intervals under harsh conditions.

3.5 Twin Tiger Bucket Teeth

At Siderwin, twin tiger teeth are developed for large excavators and severe rock layers.

Key characteristics:

- Dual penetration points

- Stable cutting force

- Reduced vibration during digging

4. Forged vs Cast Bucket Teeth – Our Engineering View

At Siderwin, we manufacture both forged and cast bucket teeth, and we recommend them based on application, not marketing preference.

| Item | Forged Bucket Teeth | Cast Bucket Teeth |

|---|---|---|

| Process | Hot forging | Precision casting |

| Internal structure | Dense grain flow | Uniform structure |

| Impact resistance | Excellent | Good |

| Wear resistance | High | Medium–high |

| Typical use | Mining, hard rock | Construction, earthmoving |

At Siderwin, we recommend:

- Forged bucket teeth for high-impact, hard-rock applications

- Cast bucket teeth for general-purpose and cost-sensitive projects

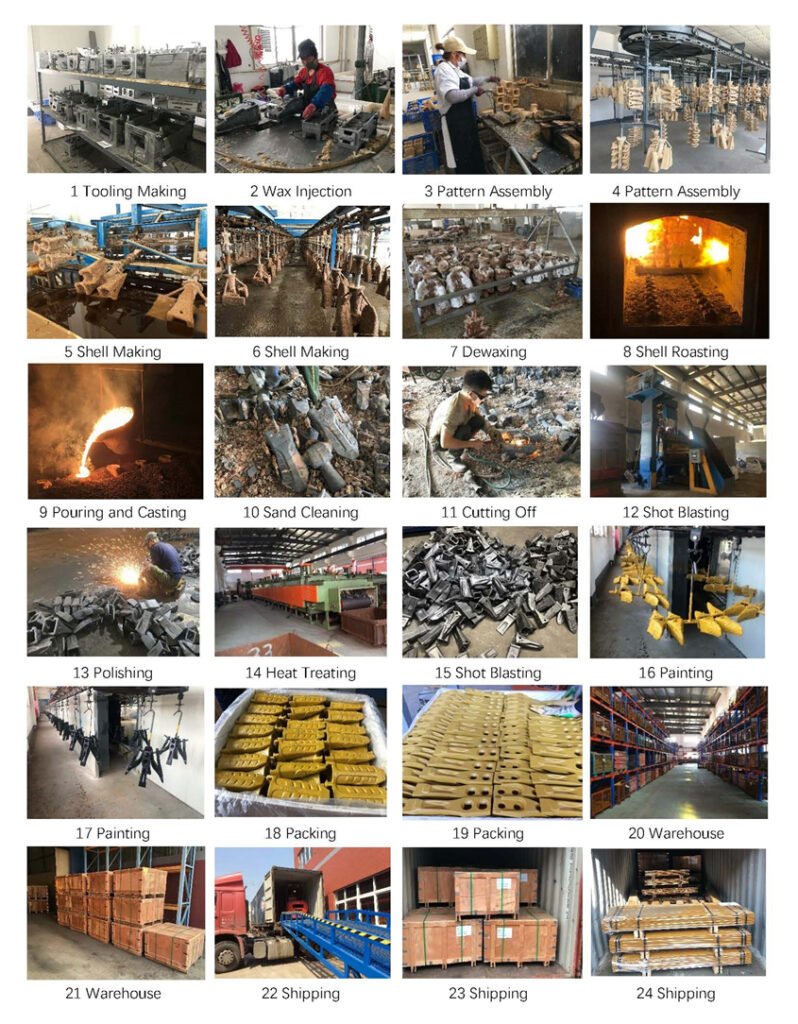

5. Bucket Tooth Manufacturing Process at Siderwin

5.1 Raw Material Control

At Siderwin, we select high-strength alloy steel specifically developed for wear parts. Raw materials are inspected to ensure chemical composition stability before entering production.

5.2 Forging or Precision Casting

Depending on tooth type, we apply:

- Hot forging to refine grain structure and improve toughness

- Precision casting to achieve accurate geometry and uniform wall thickness

Each process is selected based on performance requirements, not just cost.

5.3 Heat Treatment – The Core Process

At Siderwin, we consider heat treatment the most critical step.

We use:

- Controlled quenching

- Precision tempering

- Hardness gradient management

This ensures:

- A hard surface for wear resistance

- A tough core to absorb impact energy

5.4 Machining and Finishing

At Siderwin, we ensure:

- Accurate adapter fitting surfaces

- Stable pin holes

- Smooth stress transition areas

This guarantees secure installation and reliable performance in the field.

5.5 Quality Inspection and Testing

Every production batch at Siderwin undergoes:

- Dimensional inspection

- Hardness testing

- Surface defect checks

We also support third-party inspection and certification upon customer request.

6. Bucket Tooth System: Teeth, Adapter, Pin

At Siderwin, we always emphasize that bucket teeth work as part of a complete system.

Correct matching of:

- Tooth

- Adapter

- Pin and retainer

prevents tooth loss, adapter damage, and abnormal wear.

We provide complete GET solutions, not just individual parts.

7. How We Help Customers Select the Right Bucket Teeth

7.1 Based on Working Material

At Siderwin, we guide customers as follows:

| Working Material | Recommended Tooth |

|---|---|

| Sand / soft soil | Standard tooth |

| Clay / compact soil | Rock tooth |

| Hard rock | Tiger tooth |

| Mining / quarry | Heavy-duty or forged tooth |

7.2 Balancing Wear Life and Penetration

We help customers understand that:

- Higher penetration increases digging speed but accelerates wear

- Higher wear resistance extends life but reduces cutting aggressiveness

The right balance depends on the project goal.

7.3 Machine Size and Bucket Design

At Siderwin, we adjust tooth geometry and thickness based on:

- Excavator tonnage

- Bucket width

- Working depth

7.4 Operating Environment

We consider:

- Impact frequency

- Abrasive content

- Temperature conditions

For frozen ground or hard rock, penetration-focused designs are recommended.

8. Common Bucket Tooth Problems We Help Solve

Fast Wear

At Siderwin, we usually identify incorrect tooth selection or insufficient hardness.

Tooth Breakage

Often caused by poor heat treatment or extreme impact conditions. We recommend forged teeth with higher toughness.

Adapter Damage

Usually the result of delayed tooth replacement. We advise replacing teeth at 30–50% wear.

9. When Should Bucket Teeth Be Replaced?

At Siderwin, our recommendation is clear:

- Replace bucket teeth when wear reaches 30–50% of original size

- Avoid exposing the adapter nose

This practice significantly reduces repair costs.

10. Mixing Bucket Tooth Types – Our Practical Advice

At Siderwin, we often recommend:

- Tiger teeth in the center positions

- Standard or rock teeth on the sides

This configuration improves penetration while protecting the bucket edges.

11. OEM Compatibility and Customization

At Siderwin, our bucket teeth are compatible with major OEM systems, including:

- CAT

- Komatsu

- Volvo

- Hitachi

- Doosan

- Hyundai

We also support custom bucket teeth based on drawings or samples.

12. Why Customers Choose Siderwin Bucket Teeth

At Siderwin, we combine manufacturing expertise and real application experience.

Our advantages include:

- Strict raw material control

- Advanced forging and casting processes

- Optimized heat treatment

- Customizable specifications

- Support for third-party inspection

- Stable export quality

Our goal is to help customers reduce total operating cost, not just unit price.

13. Conclusion

At Siderwin, we believe bucket teeth selection is a technical decision, not a simple purchase. The right bucket teeth improve:

- Productivity

- Reliability

- Equipment protection

- Cost efficiency

With Siderwin bucket teeth, customers gain a reliable, long-term solution for excavation and mining projects.